The power tools are made for high-end work but after a certain time, these tools lose their power and start functioning badly. Ultimately, you have to replace or repair them, even after putting a lot of effort in maintaining them. So, next time when you think of buying the power tools, make sure to check the huge collection of power tools present at nri industrial equipment selling site. Here, you can find a wide set of specifications in power tools such as size, model, and various other features.

The power tools are made for high-end work but after a certain time, these tools lose their power and start functioning badly. Ultimately, you have to replace or repair them, even after putting a lot of effort in maintaining them. So, next time when you think of buying the power tools, make sure to check the huge collection of power tools present at nri industrial equipment selling site. Here, you can find a wide set of specifications in power tools such as size, model, and various other features.

Thus, when you get ready to repair your tools check first what else needs repair or replacement to save time. Below are some tools that need replacement very often so if you have them, try to check on the site and purchase the one with high quality to save your money in future.

Table of Contents

1. Power cords

One power tool that is vulnerable to wear and damage is power cords. The rubber insulation becomes fray or damaged during use which then exposes the tool’s wiring. An exposed damaged wire is a hazard, and you need to replace or fix it immediately. Also, a tool’s power cord can become loose, or the protector can come off. So, as you perform maintenance on your power cord, ensure you confirm the prongs on the plugs are not loose or bent.

One power tool that is vulnerable to wear and damage is power cords. The rubber insulation becomes fray or damaged during use which then exposes the tool’s wiring. An exposed damaged wire is a hazard, and you need to replace or fix it immediately. Also, a tool’s power cord can become loose, or the protector can come off. So, as you perform maintenance on your power cord, ensure you confirm the prongs on the plugs are not loose or bent.

2. Power switch

When your tool has a bad power switch, it will keep it from starting as you try to turn it on. Most time the power switch wears out or burns out with use. So to check it, remove the housing of the tool. Note, some tools may need you to dig more before you remove the housing. Also, as you check what’s wrong with your power switch, remember to check the wiring too before you decide what you are replacing. Damage from the heat could also be the reason the switch burns, melts, or becomes discolored.

When your tool has a bad power switch, it will keep it from starting as you try to turn it on. Most time the power switch wears out or burns out with use. So to check it, remove the housing of the tool. Note, some tools may need you to dig more before you remove the housing. Also, as you check what’s wrong with your power switch, remember to check the wiring too before you decide what you are replacing. Damage from the heat could also be the reason the switch burns, melts, or becomes discolored.

3. Batteries

One of the common replacement tool parts is batteries. If you have a cordless tool, you may have to replace the batteries more so if you run them every day. Because of heat, your battery fuel cells can burn out. This causes the battery to overheat or as you store it in a high heat area it will make the battery burn out and you will have to replace them. Also, to make a working connection with the charger, batteries need some power in their cell. Thus, if the battery runs out, you will have to replace it.

One of the common replacement tool parts is batteries. If you have a cordless tool, you may have to replace the batteries more so if you run them every day. Because of heat, your battery fuel cells can burn out. This causes the battery to overheat or as you store it in a high heat area it will make the battery burn out and you will have to replace them. Also, to make a working connection with the charger, batteries need some power in their cell. Thus, if the battery runs out, you will have to replace it.

4. Drive belts

Belts are essential to help motors operate. The drive belts are loops of rubber that circle two shafts that are rotating. In this way, they drive energy on each shaft alternatively, hence enabling the power tool to run. Therefore, drive belts are common replacement parts as with time they deteriorate. Also, in the case where the tool is not in use for a long time, it can break down. Plus, they are prone to dry rot because the belts are made of rubber and can crack losing their elasticity.

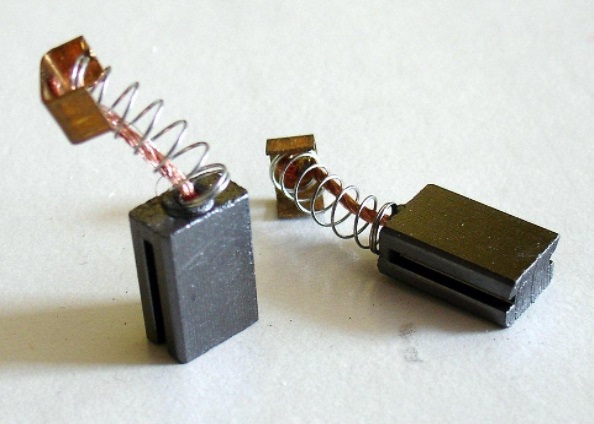

5. Carbon brushes

It is common to replace or repair carbon brushes in power tools. The carbon brush is essential in conducting electrical current through the tool to rotating parts. By just using them, the carbon brushes will naturally wear out. Plus, some signs can help you know if the carbon brushes are ready for replacement. For instance, your tool may be having challenges starting or may not even start at all.

6. Accessories and bits

In every power tool, it is obvious that at some point the accessories will wear out. Drill bits and saw blades wear down through use over time. Sometimes they will chip or snap into two. Other times they get lodged in a piece of brick, wood, or concrete. Since bits come in various types of materials, ensure you choose the one right for the job at hand.

To conclude, as you select replacement parts for your power tool, make sure you research the right part for the specific tool you have. If you select a replacement part that is not a match of your tool it leads to further problems, additional repairs, and safety issues. Consult with your tool’s manufacturer if you have any queries about the size or kinds of replacement parts you need.