A well-constructed asphalt surface is crucial for the safety of motorists and pedestrians alike. Unfortunately, even the sturdiest paved surfaces can become damaged with time and use.

A well-constructed asphalt surface is crucial for the safety of motorists and pedestrians alike. Unfortunately, even the sturdiest paved surfaces can become damaged with time and use.

When it comes to fixing these damages, asphalt milling is one of the most effective solutions available. This process entails using a milling machine with rows of cutting teeth on a drum.

Table of Contents

Improved Traffic Flow

Asphalt milling involves removing a thin pavement layer to correct surface imperfections, ensuring the pavement’s structural integrity remains intact. This method also helps prevent future deterioration and delays the need for more extensive repairs or complete reconstruction.

A smoother road surface enhances traction and reduces the likelihood of vehicles skidding, especially in adverse weather conditions. This improves driving safety by allowing drivers to maintain vehicle control, stay within lane boundaries, and follow curve radius.

Road milling also recycles old asphalt materials into reclaimed asphalt pavement (RAP) for use in new projects. This minimizes the need for new aggregates and reduces waste and energy consumption.

Increased Structural Integrity

Milling is an effective pavement repair technique that helps restore a roadway’s structural integrity. It is also a good way to reduce the amount of new asphalt needed in an overlay project.

The asphalt milling machine uses a large drum with carbide-tipped teeth to remove and grind the surface of the existing road. The asphalt is collected and reused as recycled aggregate in the new road.

Researchers will conduct deflection testing (falling weight and lightweight deflectometers) to measure stiffness changes in HMA layers before and after milling. They will also use a portable seismic pavement analyzer to assess the stiffness of milled surfaces non-destructively.

Increased Lifespan

In addition to improving the driving experience, asphalt milling increases the lifespan of a pavement. It corrects surface issues such as rutting, raveling, and bleeding that deteriorate asphalt surfaces over time.

Pavement milling also eliminates the need to raise the road surface by overlaying a new layer. This saves construction time and reduces traffic disruption.

The pavement milling process allows the use of RAP (reclaimed asphalt pavement) in new hot-mix asphalt paving projects. This provides a more environmentally responsible approach to pavement maintenance and repair. This helps reduce landfill waste and improve sustainability for businesses transporting goods and services.

Reduced Traffic Congestion

Road milling helps reduce traffic congestion during the repair process by selectively targeting only damaged sections. This minimizes construction duration and supports economic productivity.

Aside from preventing potholes and cracks, asphalt milling creates a smoother surface for better vehicle traction. This makes driving more comfortable and safe, especially in bad weather.

Airborne crystalline silica dust generated during milling reduces workers’ risk of respiratory illness. Additionally, the milled asphalt is reused as aggregate for new pavement, saving resources and reducing environmental impact. This reduces trucking and material waste and long-term maintenance costs for road owners. This also translates to reduced carbon emissions.

Reduced Construction Time

Asphalt milling helps reduce the need for road repairs by identifying and fixing major structural damages underneath the surface. It addresses common road problems, including rutting, raveling, and bleeding, which occur when the aggregate and asphalt separate.

The resulting smooth and even surface provides a comfortable driving experience and reduces vehicle wear, making it safer for everyone to use the roadways. Milling tools also minimize traffic disruptions during construction by reducing the duration of road repairs. Additionally, the ability to recycle the milled material minimizes the need for additional raw materials and energy consumption. This makes asphalt milling an environmentally friendly and sustainable maintenance practice.

Reduced Environmental Impact

Pavement milling recycles the old asphalt surface and uses it as the aggregate in new pavement. This reduces the need to produce new raw materials and lowers environmental impacts.

Asphalt milling also creates a smoother, safer, and more stable road surface, reducing the likelihood of slips and falls on the paved roadway. This allows traffic to flow freely with minimal disruption and saves time and money for business owners.

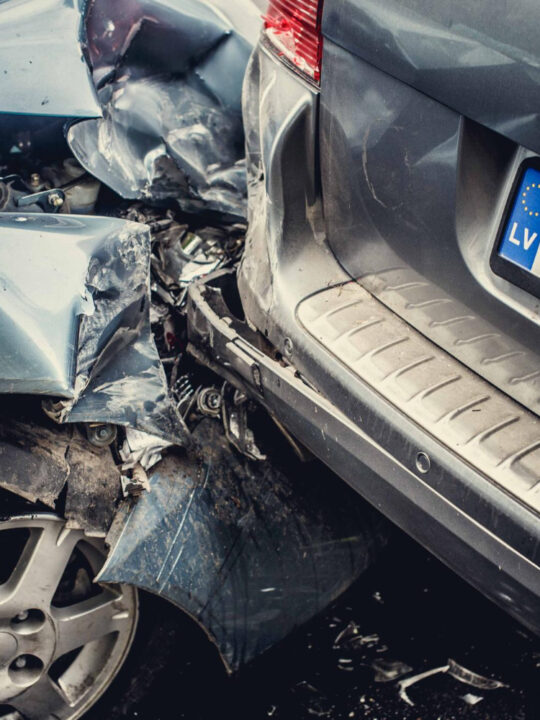

A milling machine has a large drum with rows of carbide-tipped teeth, known as road milling teeth that cut into the paved asphalt surface. The milling drum then grinds up the removed material into small pieces. This is used for different purposes, such as removing damage from accidents or fires, correcting rutting and raveling, and repairing potholes.